In an earlier article, I mentioned my encounter with a

Music Man Luke and its unusual flaking finish. The polyester finish -- usually the toughest, most impervious of guitar finishes -- was very mysteriously lifting and peeling away from the body in brittle chunks. A potato chip-sized piece even fell away as I was examining the guitar, landing on the floor with a distinct

'plik'.

|

| This Music Man Luke's original flaking finish. |

Our good buddy Reggie, the owner of this guitar, had left it in the care of a repair shop where it languished unattended, for -- get a load of this -- not days, not weeks, but several months! The shop owner claimed that he was 'waiting for the Music Man decal'.

Sure. Waiting for it to materialize out of thin air, maybe. And it didn't occur to him to at least start working on the body? Amazing.

|

| Headstock area where more of the original finish seems to be peeling off |

When Reggie told me how long he had been waiting on that guitar, I instantly thought of my luthier friend Luca Quacquarella. Showing him a few pictures of the Les Paul BFG that Luca had refinished for me convinced Reggie that our Italian friend was indeed the man for the job.

Luca had to clear his backlog of repairs before he could start work on the Music Man. But within a week, Reggie sent me this picture.

|

| The Luke stripped down |

To Ernie Ball/Music Man's credit, they did choose a pretty clean piece of alder for this guitar. Nicer woods are normally reserved for where the wood grain would be visible, like in clear or sunburst finishes. More gnarly woods are used for opaque colors like the black sparkle finish this guitar came in.

With the body stripped down to the bare wood, the refinishing process could finally start!

Luca recommended going with an all nitrocellulose finish for this guitar. Nitro finishes are much more labour intensive to apply but they allow the guitar to breathe and resonate better than the plastic, polyester finishes. Perhaps not a significant difference tone-wise on a solidbody guitar like this one, but a huge difference when it comes to acoustic and hollowbody instruments.

With a nitrocellulose finish, up to ten coats are needed for a mirror-like shine. Each coat must be allowed to thoroughly dry for a day or two, then wet sanded with very fine grit sandpaper before the next coat.

Many major guitar manufacturers that claim to use nitrocellulose usually mix in a plasticizer to allow for fewer coats to achieve a high gloss finish. Far less labour intensive and they are able to get the guitars out the door more quickly.

Luca started off by spraying a couple of initial coats of white to act as a base coat.

|

| Initial white base coat |

Luca has managed to source a local supply of nitrocellulose paints in a stunning variety of colors. Because of current restrictions on importing paints and flammable liquids, a license would be required if he were to order them by mail through companies in the US like Stewmac.com

|

| Metallic purple nitrocellulose paint |

After a few tests of the purple lacquer mixed in with different degrees of black tint to decide on the final shade of metallic purple, the next step was choosing the right size of metal flake or paint glitter.

That's right folks, metal flake is available in many colors and in several sizes! Too small, and the effect is too subtle. Too large, and it's Mardi Gras time!

|

| Metallic purple glitter flakes |

Decisions, decisions..

After a couple of test runs, Reggie and Luca agreed upon the metal flake size that they felt would work best. And although the jar says 'purple metallic flake', the end result shows a mix of purple, pink, gold and silver flecks. Real nice! But unfortunately something that doesn't show up readily in photos.

And through the entire process, Reggie was not a mere bystander.

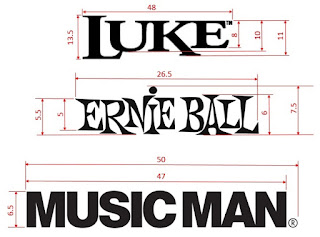

Luca has a go-to guy he always uses to make his custom guitar decals. And when the finish was stripped off the headstock, the original Music Man Luke logo on the front and 'Made In San Luis Obispo' lettering on the back, went along with it.

Reggie's challenge was to put his design skills to use to recreate the headstock logo in graphic form. For Luca's decal guy to reproduce it properly, it also needed to be to the exact scale as it would finally appear on the guitar.

Not bad, Reg. Not bad at all. Even Steve Lukather wouldn't be able to tell that this was a reproduction decal.

|

| Music Man Luke decal applied to headstock |

And since his guitar was undergoing a major refinish, Reggie decided to also source for a set of stainless steel Allen screws to replace the rusted height adjustment screws of the bridge saddles.

|

| In the process of installing new stainless steel saddle screws |

Why on Earth guitar manufacturers would use ordinary metal screws on a part of the guitar that would be constantly exposed to sweat and grime from the player's hand, I could never understand. And on a high-end guitar, no less. Once those suckers rust up, any attempt at adjusting saddle height becomes impossible. And stainless steel screws are cheap too.

Luca's initial plan was to follow the original Music Man style of lacquering the back of headstock up to the first fret, and using a mineral wax composite for the rest of the neck for that bare wood feel. In the end I was quite relieved when he decided to hard lacquer the back of the entire neck. Minimal chance of that thing moving, ever!

He must have heard my protestations and my mentioning playing another Music Man Luke recently where the neck was starting to twist, resulting in several buzzing frets along the treble side only, despite the high action.

It's always a crap shoot when going with an oil finished neck. Especially in Singapore's high humidity and warm weather. Factor in a highly figured maple neck, like what Music Man uses, and the odds of having a warping neck increase several-fold.

Just my humble experience. Your own experience may vary depending on the climate and humidity of your country and the quality of your environment where you store your guitars.

After spraying the white undercoat, Luca next applied several coats of the metallic purple paint, allowing each coat to dry and wet sanding between coats as mentioned. The purpose of wet sanding between coats is to ensure that the finish has no bumps, drips or 'orange peel', a fine dimpled texture as a result of overspray. All imperfections and uneveness must be removed before the next coat is layered otherwise they will all show up in the final finish in all their lumpy glory. Which will look awful on close inspection.

|

| Checking in bright light for spray flaws |

The final coat is then polished on a buffing machine to a high gloss lustre.

And in case you're wondering, Luca does all his refinishes in a proper spray booth with a suitably sized exhaust fan. And did I mention his white haz-mat suit, gloves and respirator? Nitrocellulose is highly carcinogenic and is not something you would want to inhale in its liquid form!

Stay tuned for Refinishing A Music Man Luke Part 2 and the final reveal!